Twin-Forming Machine

The Twin-Forming Machine adopts the exclusive patented technology design "Pick Feeder Patent",...

DetailsEgg Pancake Forming Machine

Egg Pancake Forming Machine replaces the traditional production methods of kneading by hand...

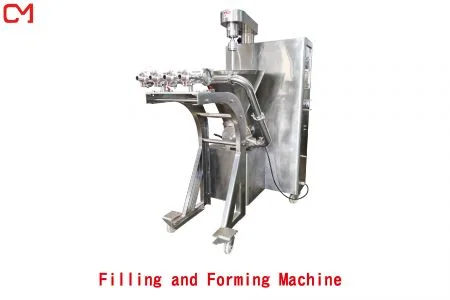

DetailsFilling and Forming Machine

The Filling and Forming Machine utilizes a screw-driven mechanism with a bottom paddle discharge...

DetailsRoller Forming Machine

The Roller Forming Machine can simply replace different molds to change the product shape,...

DetailsPatty Forming Machine

Patty Forming Machine can continuously form meat products of various shapes, not only round...

DetailsMulti Forming Machine

Multi Forming Machine can be used to make food of various shapes and sizes. The multi-purpose...

DetailsStirring & Mixing Machine

The Stirring & Mixing Machine uses a unique stirring blade to quickly mix water and flour,...

DetailsBatter Coating Machine

Batter Coating Machine is divided into Diving-Type Batter Coating Machine and Waterfall-Type...

DetailsFlour Coating Machine

Flour Coating Machine is divided into Rotary-Type Flour Coating Machine and Spiral-Type Flour...

DetailsCoiled Heat Exchanger

Coiled Heat Exchanger is an upright design, is a fully insulated and insulated structure that...

DetailsContinuous Frying Machine

The Continuous Frying Machine is made of stainless steel, which meets the requirements of food...

DetailsContinuous Filter Machine

The Continuous Filter Machine is made of stainless steel, which meets the requirements of food...

Details