IQF

Rapid Freezer, Freezer, Individual Quick Freezing, Spiral Type IQF, Tunnel Type Freezer, IQF Tunnel Freezer, IQF Spiral Freezer

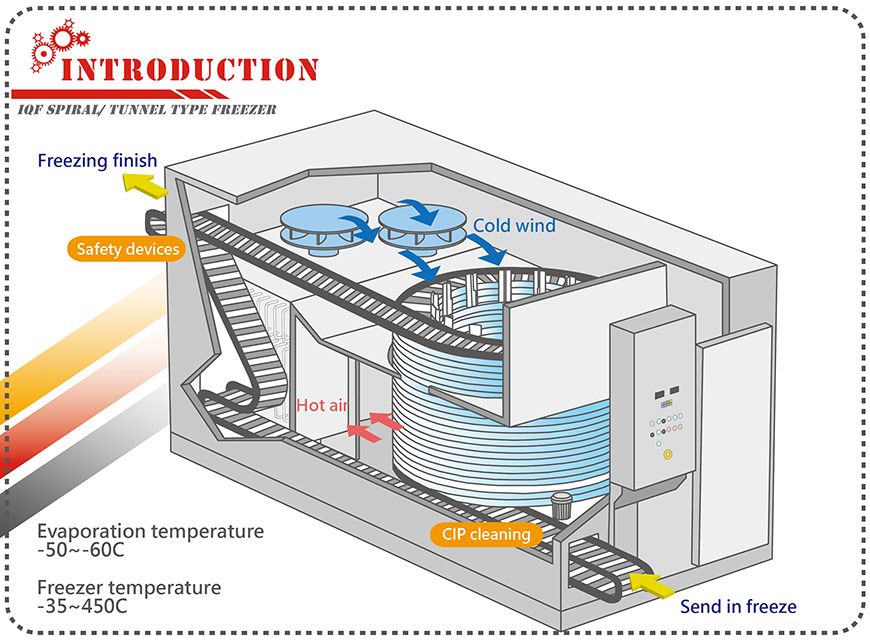

IQF is a continuous freezing equipment, which is divided into tunnel type and spiral type. It is extremely easy to automate arrangements in the production line, it can greatly reduce the use of manpower and improve productivity, and the improved equipment not only greatly reduces the volume, but also achieves long-term operation without frost, and can be assembled in the factory. The operation panel is simple, and the electronic chip stacking board control circuit is used to display the operation status (temperature in the warehouse, production time, abnormal display), so that the operator can fully understand the operation situation. Reducing the traditional track can greatly reduce the distance of the conveyor belt and concentrate the cooling effect to achieve the ideal section area.

The whirling blowing is a cycle blowing from top to bottom, the temperature change in the warehouse is small, the freezing time is saved, the freezing effect of the product is greatly increased, the food parts are blown evenly, and the deformation of the product due to rolling extrusion is reduced. Without affecting the product structure and taste, it can meet the requirements of maintaining high freshness.

Chuang Mei can provide customized services according to customer needs to solve customer process problems. If you have any needs, please feel free to contact us.

Features

- Quick cooling speed: fast turning speed and good efficiency.

- Convenience of installation and movement: The volume is greatly reduced, and it can be transported and installed without disassembly, and the construction can be greatly shortened after installation in the field.

- Operation control: simplified operation, central control.

- Follow-up maintenance: less maintenance construction and less wear and tear.

- It can be specially designed and manufactured with the on-site space.

- Large capacity freezing, 100% production capacity.

- Frameless: The innovative and improved frameless track design not only doubles the capacity, but is not as easy to stain and difficult to clean as the traditional stock design.

- Easy to clean, 100% hygienic: The mesh belt is the most convenient to clean, maintains the sterile environment of the conveyor belt, and guarantees hygiene and safety.

- Display of the operation status (temperature in the warehouse, production time, abnormal display) allows the operator to fully understand the operation status.

- The whole machine is made of stainless steel.

- It can be customized according to customer needs.

- The whole machine is in compliance with food hygiene and safety regulations.

- 100% made in Taiwan.

Applications

Applies to:

Fish goods : After the processing is completed, they are quickly frozen in batches, and then transferred to the general freezer.

Slaughterhouse : Rapid freezing of chickens, ducks, geese, pigs, cattle, sheep.

Pizza, mochi, dumplings, dough, aquatic products and other products are quickly frozen, sterilized, and vacuum packed.

- Applications

- Youtube

-

IQF is a continuous freezing equipment, which is divided into tunnel type and spiral type. It is extremely easy to automate arrangements in the production line, it can greatly reduce the use of manpower and improve productivity, and the improved equipment not only greatly reduces the volume, but also achieves long-term operation without frost, and can be assembled in the factory.

IQF - Rapid Freezer, Freezer, Individual Quick Freezing, Spiral Type IQF, Tunnel Type Freezer, IQF Tunnel Freezer, IQF Spiral Freezer | 45 Years Food Forming, Coating & Cooking Machinery Manufacturer Since 1977 | CHUANG MEI INDUSTRIAL CO.

Based in Taiwan since 1977, CHUANG MEI INDUSTRIAL CO. has been a food processing machinery manufacturer. Their main processing machines, including IQF, food forming, coating, frying and cooking machinery, as well as food refrigeration coolers, conveyors and lifter equipment.

CHUANG MEI Industry has more than 45 years of experience in food processing machinery manufacturing. It has complete self-development ability, provide customized and accurate humanistic consideration design, and are consistent with comprehensive, formal and multi-functional opportunities. CHUANG MEI focuses on producing of aquatic food processing and conditioning machinery and offering friendly services to customers.

CHUANG MEI, CM has been offering customers food cooking machines, both with advanced technology and 45 years of experience, CHUANG MEI, CM ensures each customer's demands are met.