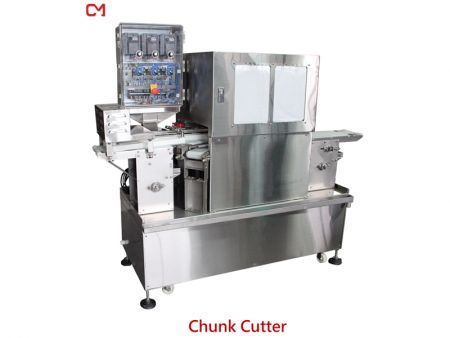

Chunk Cutter

Food Bevel Cutter, Pine Leaf Crab Oblique Cutting Equipment, Automatic Slicer, Crab Stick Production Equipment

The Chunk Cutter is suitable for the oblique or longitudinal cutting of food. The rotating blade is used for fixed-size cutting. When cutting products, the knife rotates instantly and quickly, which can accurately supply materials, and can complete uniform cutting regardless of the thickness of one piece, and can perform cutting processing for two products at a time, saving floor space.

Chuang Mei can provide customized services according to customer needs to solve customer process problems. If you have any needs, please feel free to contact us.

Features

- Suitable for the oblique or longitudinal cutting of food.

- The rotating blade is used for fixed-size cutting.

- Can perform cutting processing for two products at a time, saving floor space.

- The Pine leaf crab is crab flavor stick is continuously obliquely broken into shape.

- The whole machine is made of stainless steel.

- It can be customized according to customer needs.

- The whole machine is in compliance with food hygiene and safety regulations.

- 100% made in Taiwan.

Applications

Can be applied to all kinds of vegetables and food that need to be cut diagonally.

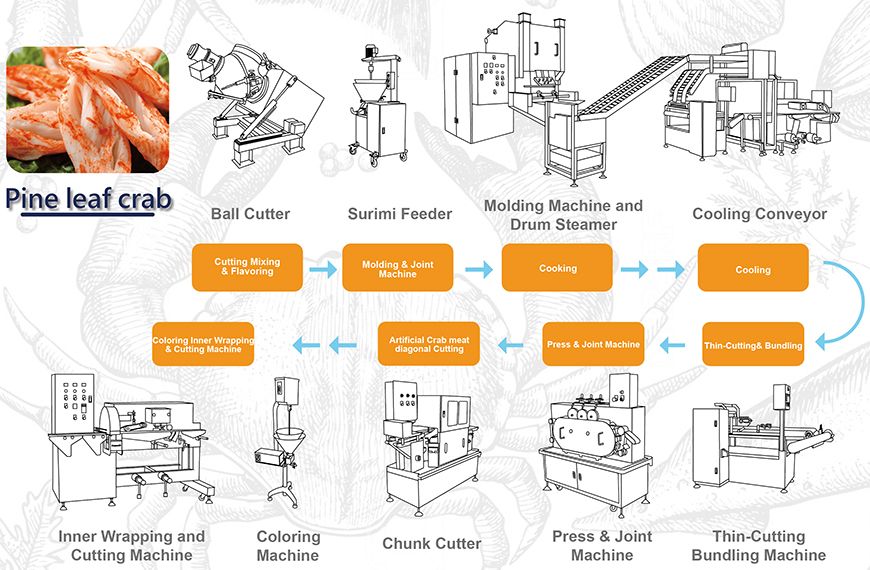

The Surimi Making Machine can make crab sticks, scallops, pine leaf crab, and lobster sticks.

The crab sticks and scallops are equipped with Homogenizing Machine, Surimi Feeder, Molding Machine and Drum Steamer, Cooling Conveyor, Thin-Cutting & Bundling Machine, Surimi Coloring Machine, Inner Wrapping & Cutting Machine.

The Pine leaf crabs are equipped with Homogenizing Machine, Surimi Feeder, Molding Machine and Drum Steamer, Cooling Conveyor, Press & Joint Machine, Chunk Cutter, Surimi Coloring Machine, Inner Wrapping & Cutting Machine.

The lobster sticks are equipped with Homogenizing Machine, Surimi Feeder, Surimi Coloring Machine, Inner Wrapping & Cutting Machine.

- Applications

- Youtube

The Chunk Cutter is suitable for the oblique or longitudinal cutting of food. The rotating blade is used for fixed-size cutting. When cutting products, the knife rotates instantly and quickly, which can accurately supply materials, and can complete uniform cutting regardless of the thickness of one piece, and can perform cutting processing for two products at a time, saving floor space.

Chunk Cutter - Food Bevel Cutter, Pine Leaf Crab Oblique Cutting Equipment, Automatic Slicer, Crab Stick Production Equipment | 45 Years Food Forming, Coating & Cooking Machinery Manufacturer Since 1977 | CHUANG MEI INDUSTRIAL CO.

Based in Taiwan since 1977, CHUANG MEI INDUSTRIAL CO. has been a food processing machinery manufacturer. Their main processing machines, including Chunk Cutter, food forming, coating, frying and cooking machinery, as well as food refrigeration coolers, conveyors and lifter equipment.

CHUANG MEI Industry has more than 45 years of experience in food processing machinery manufacturing. It has complete self-development ability, provide customized and accurate humanistic consideration design, and are consistent with comprehensive, formal and multi-functional opportunities. CHUANG MEI focuses on producing of aquatic food processing and conditioning machinery and offering friendly services to customers.

CHUANG MEI, CM has been offering customers food cooking machines, both with advanced technology and 45 years of experience, CHUANG MEI, CM ensures each customer's demands are met.